Required web technologies and cookies make our website technically accessible to and usable for you. This applies to fundamental base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

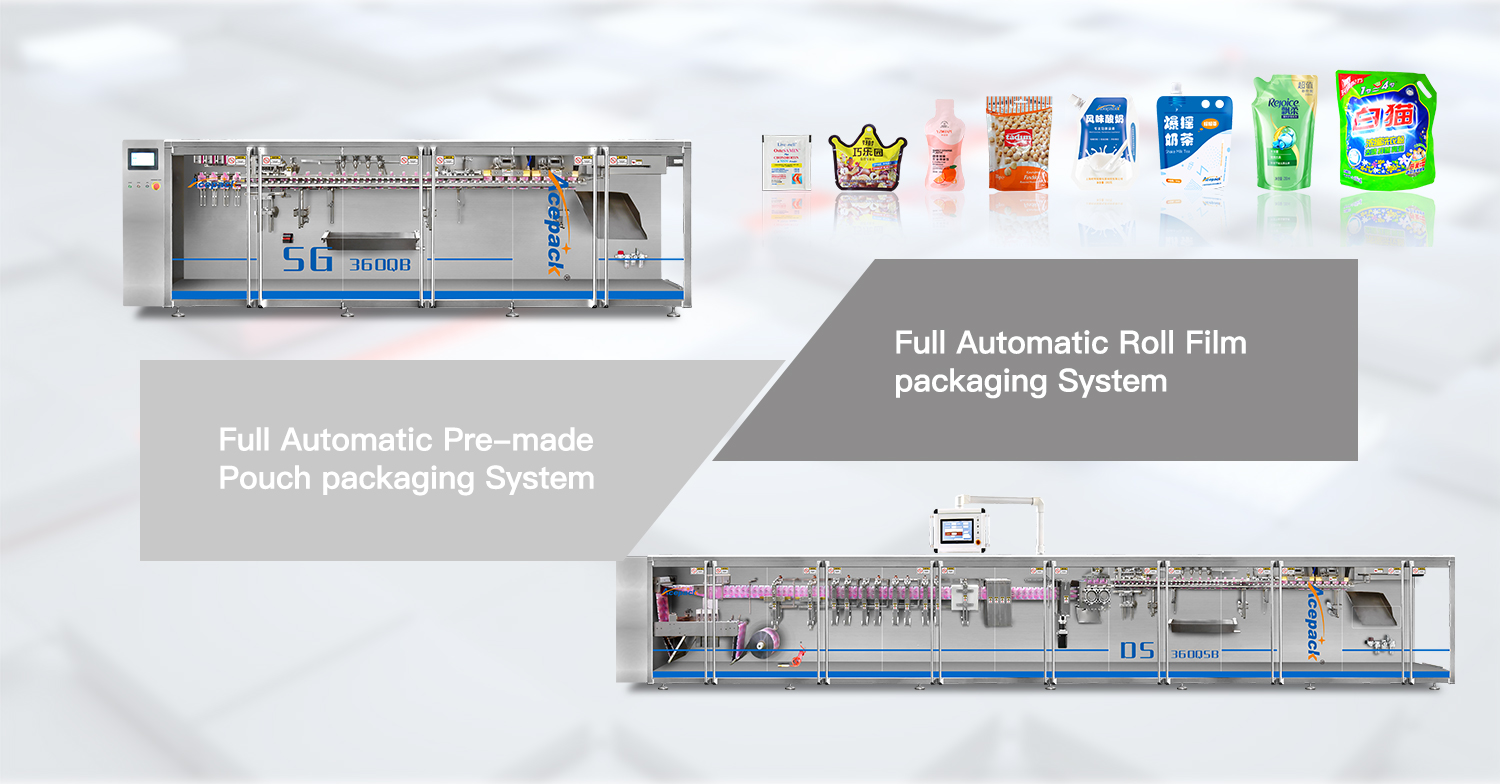

What type of bag do you want?

Flat Four-side Sealed Pouch |

Twin-link Sachet

|

Stand Up Pouch |

Zipper Stand-up Pouch |

Corner Spout Stand-up Pouch

|

Top Spout Pouch |

Special-Shaped Bag |

8-side Sealed Packaging

|

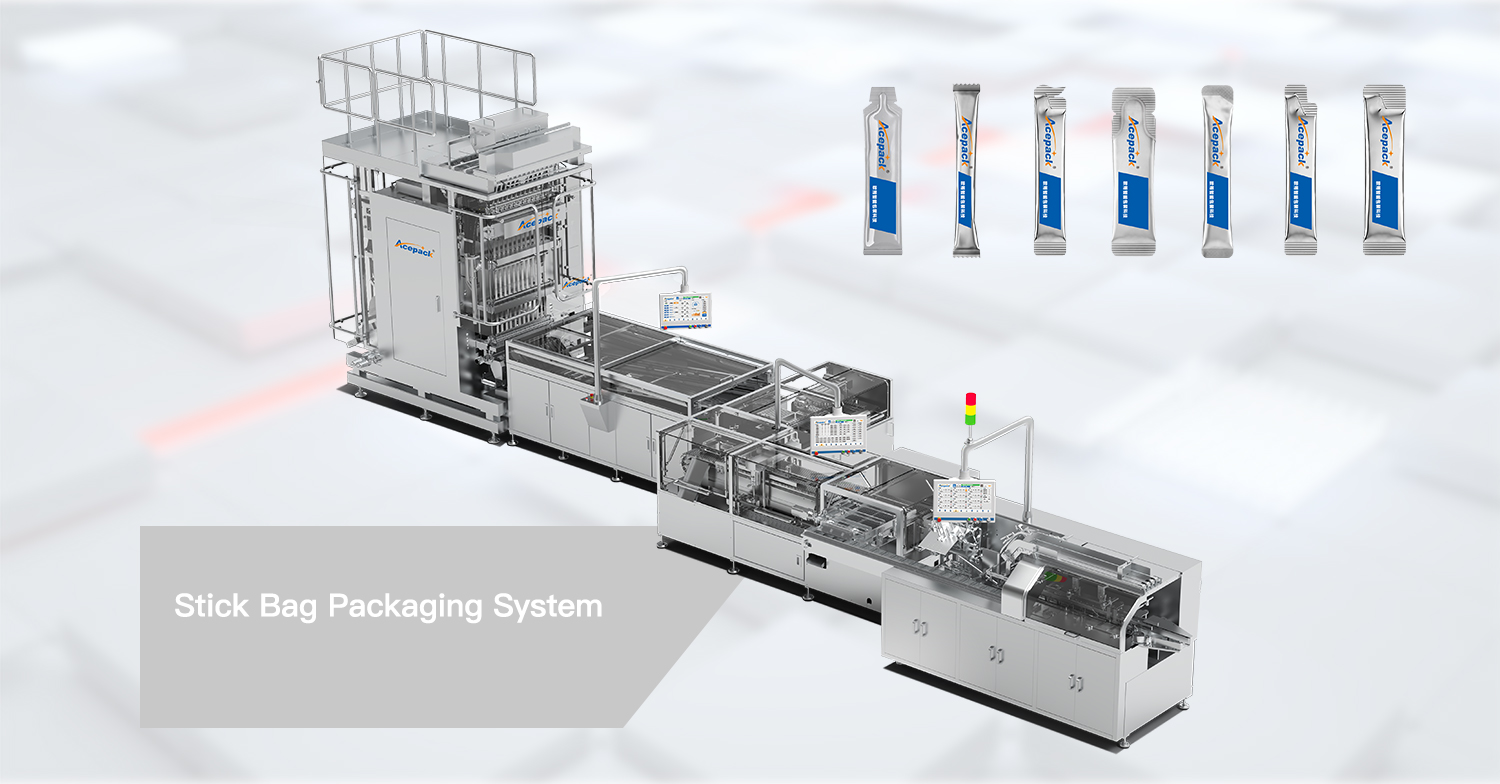

Stick Bag

|

The Comprehensive Advantages Of ACEPACK Packaging Machines

Comprehensive advantages of the machine:

1. Efficiency improvement: By applying numerous core technologies of intelligent packaging equipment, the OEE (Overall Equipment Effectiveness) is increased by more than 20%.

2. Green manufacturing: The design complies with ESG standards, promoting degradability, recyclability, and sustainable development.

3. Flexible technology: It adapts to frequent specification changes and meets the diverse market demands at the user end.

4. Form and function integration: Adhering to the international design standards of Europe, it combines advanced industrial aesthetics with high efficiency and functionality, conforms to ergonomics, is easy to operate and maintain, and enhances the user experience.

5. Wide application: It is suitable for multiple industries such as food, medicine, health products, dairy, and cosmetics.

6. Packaging renewal power: Precise packaging enhances the appearance and shelf display effect of products, strengthening market competitiveness.

7. Safety: The fully automatic system reduces human contact, lowers contamination risks, and ensures product safety and quality.

Core technologies of the horizontal packaging machine series:

① High-precision measurement and efficient production:

Utilize high-precision servo motors to drive volumetric/weight-based measurement/liquid metering pump devices, ensuring high-precision filling of liquids, particles, powders, or block-like materials. The system supports the fastest continuous operation of up to 240 packages per minute.

② High-demand multi-station synchronous control:

Utilize servo motors combined with cam structures to achieve millisecond-level synchronization of bag-making, filling, and sealing/cutting processes, reducing mechanical vibrations and enhancing stability.

③ High-standard modular design:

Quickly replace molds and film roll specifications, compatible with various bag types such as three-side sealing, four-side sealing, and self-standing bags, and capable of meeting packaging requirements ranging from 1g to 3kg.

The core advantages of the fully servo packaging machine series:

① Full servo control system:

Each execution unit (film pulling, forming, cross and longitudinal sealing, etc.) is independently equipped with a servo motor. The dynamic response speed is ≤ 0.1ms, and the positioning accuracy is ± 0.02mm.

② Adaptive motion control algorithm:

Based on real-time feedback path optimization technology, it automatically compensates for factors such as film material tension fluctuations and temperature changes, ensuring no film deviation at high speeds.

③ Optimized transmission structure:

Abandoning wear-prone components such as gears and chains, the maintenance cost is reduced by 70%. The software can quickly switch product specifications without the need for hardware adjustment.

Core technologies of the flexible packaging machine series:

① Flexible Production Switching:

By combining magnetic levitation technology with full servo technology, the product switching time is ≤ 15 seconds, and it supports flexible adaptation for various bag types/sizes.

② 4.0 Human-Machine Interaction:

Through the HMI interface or mobile APP, hundreds of preset process parameters can be called to achieve "one-click production switching", and it supports customized production of different specifications for packaging.

③ OEE Enhancement (Overall Equipment Effectiveness):

The machine can switch between intermittent and continuous operations, and is compatible with prefabricated bags and roll film packaging, meeting the fragmented order requirements of various industries such as food and medicine.

④ APM Management (Asset Performance Management):

APM combines data analysis, Internet of Things (IoT), and predictive maintenance technologies to help enterprises enhance their fixed asset management capabilities for equipment. Its main goal is to maximize equipment asset utilization by improving the health status of equipment fixed assets, taking proactive measures for independent professional maintenance of equipment in advance, and reducing equipment downtime to achieve production efficiency.

Core advantages of multi-column packaging machine:

① Multi-channel Parallel Control: The system supports 2 to 16 independent servo drives. With its outstanding parallel processing capability, the maximum production capacity can reach 1200 bags per minute for efficient packaging, significantly enhancing the operational efficiency of the production line.

② Customized Packaging Products: It offers highly flexible post-line customized complete line solutions to meet diverse production needs, effectively promoting the transformation of enterprises towards unmanned and intelligent production models, and improving the automation level and production capacity of the production line.

③ Higher Comprehensive Efficiency: By adopting advanced full servo control systems, the overall equipment utilization efficiency (OEE) is optimized, improving equipment operation efficiency and maximizing output. At the same time, it complies with EHS management standards, ensuring that the environmental, health, and safety standards of the production process are strictly adhered to, promoting the enterprise to achieve sustainable development.

Core advantages of the packaging production line:

① Full-process integrated control: By leveraging advanced Industrial Internet of Things (IIoT) platforms, all key equipment such as packaging machines, conveyor belts, packing robots, and palletizing AGVs are comprehensively integrated to achieve seamless connection from raw material entry to finished product exit, promoting unmanned and intelligent management throughout the production process, and significantly enhancing production efficiency and accuracy.

② Digital twin and predictive maintenance: By constructing precise virtual models, real-time monitoring and mapping of equipment operation status are carried out, combined with AI intelligent algorithms, to accurately predict the lifespan of key components (such as servo motors, heating elements), and trigger predictive maintenance orders in advance, ensuring high availability and continuous stability of production equipment, and reducing the risk of sudden failures and downtime.

③ Full-process traceability system: Utilizing RFID (anti-counterfeiting code) and QR code technologies, each package of product is assigned a unique identifier to achieve full traceability. The system records key data such as production time, batch, and process parameters, meeting the compliance requirements of international certifications such as FDA and GMP, providing enterprises with strong quality control and security guarantees, and ensuring the trustworthiness and compliance of products in the global market.

FEEDBACK FORM CONTACT WITH US

Please leave us message for your inquiry: